Consumer Electronics Assembly Lines are highly automated production processes designed to efficiently manufacture electronic devices such as smartphones, laptops, and televisions.

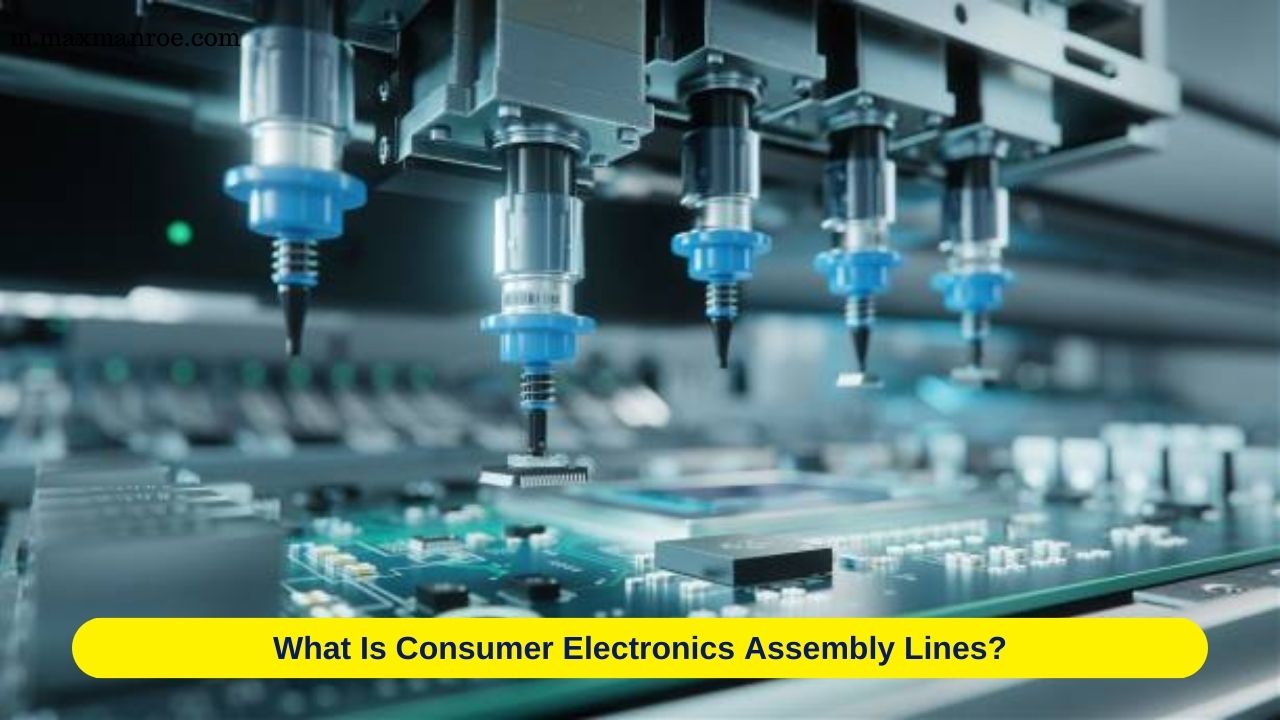

These assembly lines utilize advanced robotics and precision machinery to assemble intricate components with speed and accuracy, ensuring a consistent and high-quality end product.

Workers on consumer electronics assembly lines are often responsible for overseeing and managing the automated machinery, conducting quality control checks, and addressing any issues that may arise during the assembly process.

Continuous innovation in consumer electronics assembly line technology has led to increased production efficiency, reduced manufacturing costs, and faster time-to-market for the latest electronic gadgets.

Sustainability is becoming a key focus in consumer electronics assembly, with efforts to minimize waste, optimize energy consumption, and implement eco-friendly practices throughout the manufacturing process.

What Is Consumer Electronics Assembly Lines?

Consumer electronics assembly lines refer to the organized and automated manufacturing processes specifically designed for producing electronic devices intended for personal use.

These assembly lines are responsible for the efficient and systematic creation of items such as smartphones, tablets, laptops, cameras, televisions, and other electronic gadgets that consumers use in their daily lives.

The assembly lines are characterized by a series of interconnected workstations and machinery, often highly automated, to carry out tasks like component assembly, soldering, testing, quality control, and packaging.

Advanced robotics and precision equipment are commonly employed to ensure accuracy, speed, and consistency in the assembly process.

Workers on consumer electronics assembly lines play roles in overseeing and managing the production machinery, conducting quality checks, troubleshooting issues, and ensuring the overall smooth operation of the manufacturing process.

These assembly lines are crucial for meeting the demands of the rapidly evolving consumer electronics market, enabling mass production while maintaining high standards of quality and efficiency.

Read More: 7 Steps Solar Panel Manufacturing Techniques of 2024

9 Steps Consumer Electronics Assembly Lines

Consumer electronics assembly lines typically involve a series of steps to transform individual components into finished electronic devices.

While the specific processes can vary based on the product and manufacturer, here are general steps involved in consumer electronics assembly lines:

Component Preparation

Component preparation is a critical initial phase in the consumer electronics assembly process, marking the foundational step where raw materials and individual electronic components are readied for integration into the final product.

This stage involves meticulous attention to detail as manufacturers gather diverse elements, ranging from semiconductors and circuit boards to display screens and casings.

The quality and readiness of these components significantly influence the overall efficiency and reliability of the subsequent assembly line processes.

Precision and accuracy are paramount during component preparation, ensuring that each constituent part is in optimal condition for integration into the electronic device.

This foundational step sets the tone for the entire manufacturing process, laying the groundwork for the seamless assembly of cutting-edge consumer electronics that meet the ever-evolving demands of the tech-savvy market.

Printed Circuit Board (PCB) Assembly

Printed Circuit Board (PCB) assembly constitutes a pivotal stage in consumer electronics manufacturing, where the intricate dance of automation and precision takes center stage.

During this phase, automated machinery orchestrates the placement and soldering of electronic components onto the PCB, the backbone of any electronic device.

Microprocessors, memory chips, resistors, and capacitors are meticulously positioned with remarkable accuracy, forming the neural network that powers the device’s functionality.

The seamless integration of these components onto the PCB not only demands technological finesse but also ensures the reliability and performance of the final product.

PCB assembly sets the foundation for the electronic ecosystem, and advancements in this stage contribute significantly to the evolution of smaller, faster, and more powerful electronic devices.

As the heart of modern electronics, the PCB assembly process reflects the marriage of precision engineering and technological innovation, laying the groundwork for the next generation of consumer electronic wonders.

Subassembly Integration

Subassemblies, which may consist of several interconnected components, are integrated into the main structure of the device.

For example, a camera module may be integrated into a smartphone during this stage.

Software Installation and Configuration

Electronic devices often require the installation of software.

This step involves loading the necessary firmware or operating system onto the device and configuring it to function properly.

Testing and Quality Control

Automated testing equipment and manual inspection are used to ensure that each electronic device meets quality standards.

This step may involve functional tests, performance checks, and inspections for defects.

Final Assembly

All subassemblies are combined to create the final product.

This includes attaching displays, connecting cables, and securing components within the device’s casing.

Packaging

Finished electronic devices are packaged for shipping and retail.

Packaging may include protective materials, user manuals, and accessories.

Shipping and Distribution

The packaged products are then prepared for shipping to distributors, retailers, or directly to consumers.

This step involves logistics and coordination to ensure timely delivery.

After-Sales Support

Consumer electronics assembly doesn’t end with the sale.

Manufacturers often provide customer support, including repairs, updates, and troubleshooting, to address issues that may arise after the product has been sold.

These steps are part of a carefully orchestrated process aimed at efficiently and reliably producing consumer electronics on a large scale while maintaining high-quality standards.

Automated machinery, skilled labor, and stringent quality control measures are key components of successful consumer electronics assembly lines.

Read More: 10 Important Aerospace Component Manufacturing Processes in 2024

Conclusion

In conclusion, consumer electronics assembly lines represent a sophisticated and highly automated process designed to transform individual components into finished electronic devices for personal use.

These assembly lines involve a series of meticulously coordinated steps, from the preparation of raw materials to the final packaging and distribution of products.

The integration of advanced technologies, such as robotics and precision machinery, has significantly enhanced the efficiency and precision of consumer electronics assembly.

This has allowed manufacturers to meet the demands of a rapidly evolving market while maintaining high standards of quality and consistency.

The assembly process encompasses tasks like printed circuit board assembly, subassembly integration, software installation, rigorous testing, and final product assembly.

Moreover, the emphasis on sustainability and eco-friendly practices has become increasingly important in consumer electronics assembly.

Manufacturers are striving to minimize waste, optimize energy consumption, and implement environmentally conscious processes throughout the production cycle.

Consumer electronics assembly lines not only play a pivotal role in mass production but also contribute to innovations in design, functionality, and overall product development.

The commitment to quality control, ongoing technological advancements, and efficient logistics in the shipping and distribution phases ensure that consumers receive reliable and cutting-edge electronic devices.

Overall, consumer electronics assembly lines are integral to the dynamic landscape of the electronics industry, continually shaping the way we interact with and rely on technology in our daily lives.