Textile Machinery Manufacturers Guide serves as a valuable resource for industry professionals, providing insights into the diverse machinery types essential for textile production.

This guide comprehensively outlines the uses of various textile machinery, from spinning and weaving to dyeing and finishing, shedding light on their crucial roles in different stages of the production process.

Textile machinery manufacturers continually innovate to meet the evolving demands of the textile industry, as highlighted in this guide, which explores the latest advancements driving efficiency, sustainability, and technological integration.

Whether in the apparel, home textiles, technical textiles, or industrial textiles sectors, the guide underscores how machinery customization and flexibility contribute to meeting consumer preferences and industry-specific requirements.

As the textile industry embraces Industry 4.0, artificial intelligence, and sustainable practices, a Textile Machinery Manufacturers Guide becomes an indispensable tool for staying informed about the cutting-edge technologies shaping the future of textile manufacturing.

Textile Machinery Manufacturers Guide

The Textile Machinery Manufacturers Guide is an indispensable resource providing comprehensive insights into the diverse types, uses, and advancements in machinery crucial for the dynamic and evolving textile industry.

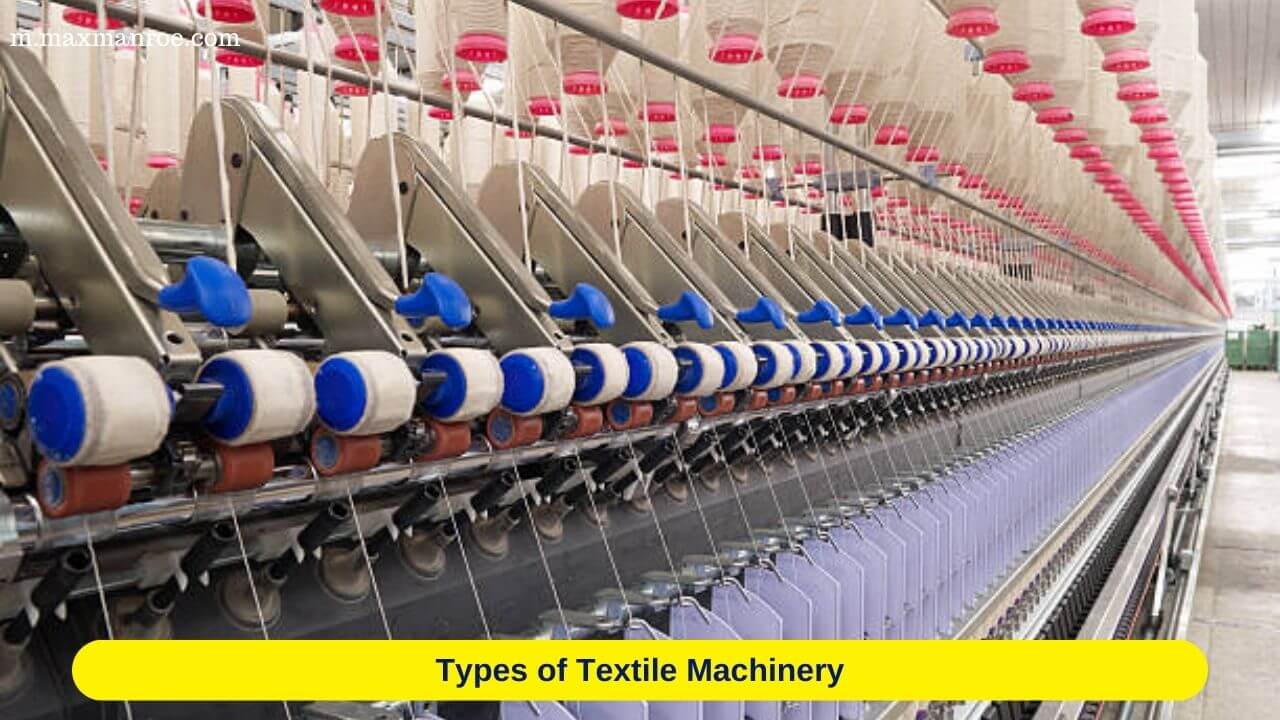

Types of Textile Machinery

Types of textile machinery, ranging from spinning and weaving to dyeing and finishing equipment, form the foundation of the industry, each playing a crucial role in transforming raw materials into a diverse array of textile products.

Spinning Machinery

Spinning is the initial stage in textile production, where fibers are transformed into yarn.

Textile mills rely on spinning machinery, which includes ring spinning, open-end spinning, and rotor spinning machines.

Ring spinning is a traditional method known for producing high-quality yarn, while open-end spinning offers higher production rates. Rotor spinning is another technique suitable for coarser yarn.

Weaving Machinery

Weaving machines are used to interlace two sets of yarn, creating fabric.

Shuttle looms, air-jet looms, rapier looms, and projectile looms are common types of weaving machinery.

Modern weaving machines, such as air-jet and rapier looms, have increased efficiency and reduced production time compared to traditional shuttle looms.

Knitting Machinery

Knitting machines produce fabrics by interlocking loops of yarn. Circular knitting machines, flat knitting machines, and warp knitting machines are the primary types.

Circular knitting machines are versatile and commonly used for producing seamless garments, while flat knitting machines are suitable for more intricate designs.

Warp knitting machines are used for net fabrics and lace production.

Dyeing and Finishing Machinery

Dyeing and finishing are crucial steps in enhancing the appearance and properties of textiles.

Dyeing machinery includes jig dyeing machines, beam dyeing machines, and continuous dyeing machines.

Finishing machinery, such as stenter frames and calendaring machines, imparts desired characteristics like smoothness, shine, and durability to the fabric.

Nonwoven Machinery

Nonwoven fabrics are produced without the traditional weaving or knitting processes.

Nonwoven machinery includes needle-punching machines, spunbond machines, and meltblown machines.

These machines are essential for producing products like medical textiles, geotextiles, and hygiene products.

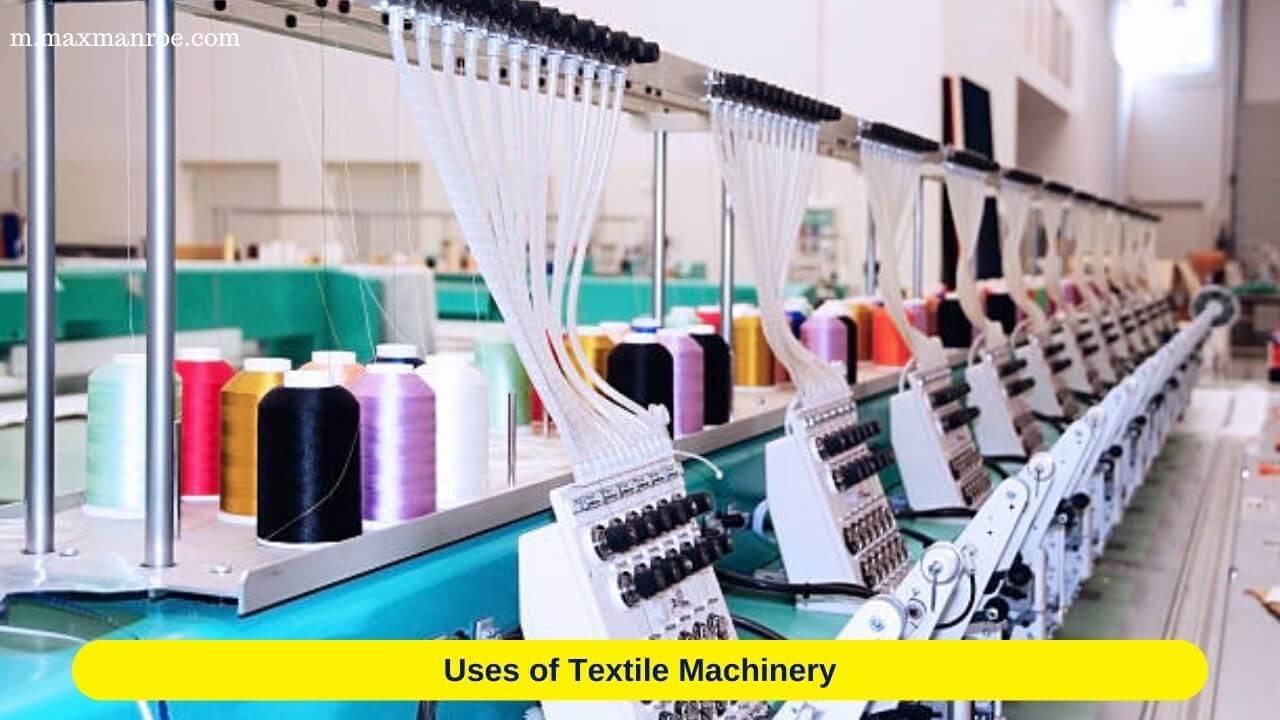

Uses of Textile Machinery

The uses of textile machinery are multifaceted, extending across diverse industries such as apparel, home textiles, technical textiles, and industrial applications, where these advanced machines contribute to the production of a wide array of high-quality and specialized textile products.

Apparel Industry

Textile machinery plays a vital role in the production of various apparel items, including clothing, sportswear, and fashion accessories.

Spinning, weaving, and knitting machines contribute to the creation of diverse fabrics that meet the demands of the ever-changing fashion landscape.

Home Textiles

Textile machinery is employed in the production of home textiles such as bed linens, curtains, and upholstery.

Dyeing and finishing processes are critical to achieving the desired colors and textures that enhance the aesthetic appeal of these products.

Technical Textiles

Technical textiles, designed for specific functionalities, utilize advanced machinery for production.

Nonwoven machinery is particularly important for applications like automotive textiles, medical textiles, and geotextiles.

Industrial Textiles

Industries such as agriculture, construction, and packaging rely on industrial textiles.

Textile machinery produces materials like tarpaulins, filters, and conveyor belts that meet the stringent requirements of these sectors.

Smart Textiles

The integration of technology into textiles has given rise to smart textiles.

Textile machinery manufacturers are developing innovative solutions to embed sensors, conductive threads, and other electronic components into fabrics, paving the way for wearable technology and smart textiles.

Advancements in Textile Machinery

Advancements in textile machinery, including the integration of Industry 4.0 technologies, artificial intelligence, and sustainable practices, are revolutionizing the industry by enhancing efficiency, customization, and environmental responsibility.

Industry 4.0 Integration

The fourth industrial revolution, known as Industry 4.0, has made its mark on the textile industry.

Smart factories leverage automation, data exchange, and the Internet of Things (IoT) to enhance efficiency.

Textile machinery manufacturers are incorporating sensors and connectivity features into their equipment, allowing for real-time monitoring and control.

Digitalization and Artificial Intelligence

Digitalization and artificial intelligence (AI) are transforming the way textile machinery operates.

AI algorithms are used for predictive maintenance, optimizing production schedules, and improving overall equipment efficiency.

Digital twinning, a technology that creates virtual replicas of physical machines, aids in simulation and analysis for better performance.

Energy-Efficient Technologies

Sustainability is a growing concern in the textile industry.

Textile machinery manufacturers are developing energy-efficient technologies to reduce the environmental impact of production processes.

Variable frequency drives, energy recovery systems, and eco-friendly dyeing methods are examples of innovations aimed at achieving sustainability goals.

Customization and Flexibility

Consumer preferences for personalized products are driving the demand for customization in the textile industry.

Advanced machinery allows for greater flexibility in terms of design, color, and texture.

Computerized control systems enable quick changeovers, reducing downtime and increasing the adaptability of textile production.

Innovations in Materials

Textile machinery advancemets are not limited to processes; they also extend to the development of new materials.

Nanotechnology, for instance, is being incorporated to enhance the properties of textiles, making them more durable, water-repellent, and resistant to stains.

Read More: Trenching Equipment for Utility Installation

Conclusion

Textile machinery manufacturers play a pivotal role in shaping the landscape of the textile industry.

The diverse types of machinery cater to the wide range of textile products, from traditional apparel to cutting-edge smart textiles.

As the industry evolves, continuous advancements in technology, digitalization, and sustainability are driving the innovation of textile machinery, ensuring its continued relevance in a dynamic and competitive global market.

This guide serves as a comprehensive overview of the types, uses, and advancements in textile machinery, highlighting the intricate interplay between technology and textile production.